8 Simple Techniques For Steel Fabrication

Wiki Article

The 20-Second Trick For Steel Fabrication And Welding

Table of ContentsThe Definitive Guide to Fabrication Steel ChartUnknown Facts About Steel Fabrication Industry4 Simple Techniques For Steel Fabrication ApprenticeshipIndicators on Steel Fabrication You Should KnowSome Known Factual Statements About Steel Fabrication Industry 10 Simple Techniques For Steel Fabrication And Welding

Furthermore, it is much faster to scale automation due to the adaptability of manufacture alternatives. Because it is slim and has a light-weight kind factor, any extra supply needed for production can be saved and also transported quickly. There are lots of methods to produce sheet steel depending on the application.Flexing, Sheet metal is positioned within a bending machine as well as bent to the desired form. Stamping, A sheet steel blank is put into a stamping press where it is created right into the wanted form utilizing a device and also pass away.

There are a number of cutting methods used, each of which supplies special characteristics that make it ideal for various applications. The earliest method of reducing is sawing. This process makes use of reducing bladeseither straight or rotaryto cut materials right into different shapes and sizes. Automatic sawing operations allow producers to achieve better precision and also accuracy in their cut parts without giving up processing speed.

Steel Fabrication Apprenticeship - Questions

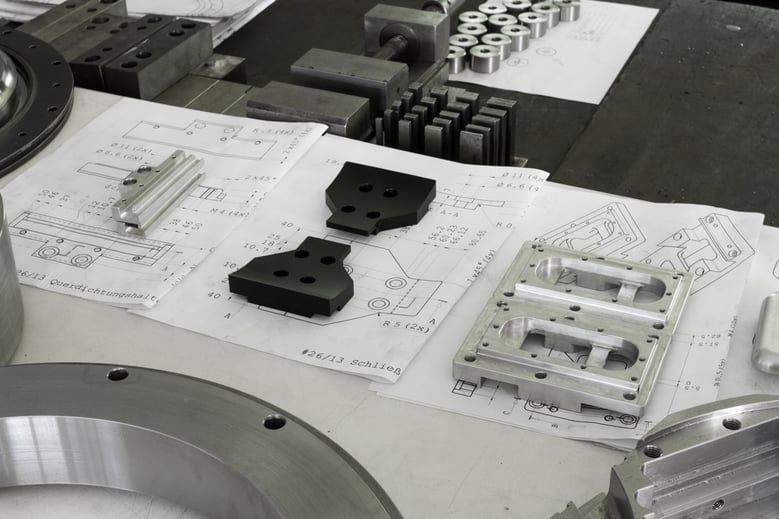

This process utilizes using a high-powered laser to reduce materials to the desired shape and size. Contrasted to various other reducing processes, it provides higher reducing precision and precision, especially for complex and also elaborate component styles. Machining Machining is a subtractive procedure, meaning it produces components as well as items by getting rid of product from the workpiece.Two of the most typical CNC machining processes are CNC milling as well as CNC transforming - fabrication steel chart. CNC milling operations count on revolving multi-point cutting tools to get rid of excess steel from a work surface. While the procedure is commonly utilized as a completing procedure, it can be used to finish a whole task. CNC transforming procedures use single-point cutting tools to remove material from the surface area of a revolving workpiece.

Steel manufacture is around you as well as you could not even understand it. Whether you're merely curious about exactly how things are made, exactly how the industry functions, or why steel construction is so essential, this short article will detail everything. We will start with the very first "W' what. Steel construction is around, yet you either don't know concerning it, haven't considered, or uncommitted.

The 6-Second Trick For Steel Fabrication Process

They are located in the building and construction sector, service center, shipyards, airfields, and everywhere in between. Usually, they originate from CNC device shops and manufacture facilities throughout the nation. Since the early days of the industrial transformation, CNC factory have been at the facility of innovation when it concerns industrial innovation, machinery, as well as automation.

So next time you drive your automobile or notice something metal making your life a lot easier, take a minute to believe of where it originated from, and also the lots of really world-changing technical explorations that have been made over hundreds of years to make it feasible. Do you require metal fabrication services? Baron Maker does it all (steel fabrication process).

Indicators on Steel Fabrication Business You Need To Know

The procedure can be utilized in making mass-produced items or custom layouts. Whether mass-produced or personalized steel fabrication business for sale made, the end items are made with a large array of steels and also their alloysstainless steel, carbon steel, light weight aluminum, copper, brass to name a few.

The old days of sawing have actually been superseded by contemporary types of cutting that make use of advanced machinery. From power tools to computer mathematical computer system (CNC) cutters, today's techniques consist of laser cutting, waterjet cutting, power scissors, as well as plasma arc cutting. Creating In manufacturing, creating is a fabrication procedure that bends or misshapes steel to produce components and also elements.

Strips or sheets of metal are constantly fed with parallel rollers that shape the workpiece right into the wanted form. Throughout the procedure of forming, the steel product does not shed its mass, only its type. Punching Punch presses are mechanical tools or machines used to punch or produce openings in steels.

Some Known Facts About Steel Fabrication Meaning.

In large manufacture procedures, industrial CNC programmed presses are made use of to produce complex designs at better output to fulfill both hefty as well as light metalwork. Shearing Utilized to trim or eliminate undesirable product from steel product, shearing is accomplished by installing two blades over as well as below the metal to produce one long, straight cut.Straight cuts are achieved by incorporating two devices, essentially blades, with one of the devices over the metal and the other one find out located listed below Learn More for using pressure. The upper blade compels the steel down onto the fixed or fixed reduced blade to fracture the item as well as complete the separation. Stamping Comparable to boxing, stamping creates an impression instead of an opening during fabrication.

Steels can differ in shape or dimension. The 3 primary kinds of welding treatments are Stick or Arc Welding, MIG Welding, as well as TIG Welding. Spot welding and stud welding are two various other flexible welding applications used in commercial metal manufacture shops.

The 6-Second Trick For Steel Fabrication Business

The tube laser cutter can reduce sophisticated patterns and openings on metal extrusions and tubes. Guillotine cutters are likewise utilized for straightforward cuts or materials that must not be revealed to the laser's higher temperatures.Laser cutters use high-power laser light beams to thaw the metal. High-pressure gas (nitrogen, air, or carbon dioxide)is utilized to blow the liquified metal out as well as end up the cut. g. powder finishing)can be made use of prior to or after the setting up to finalise the metal manufacture process. High-grade metal fabrication does not depend just on the quality of the devices as well as procedures. Having an experienced team is the most important element to ensure the best quality of the provided metal fabrication services. We have a committed steel manufacture group at Westberg Sheet Steel. You can additionally sign up with the production team of Ultralift Australia. Ultralift offers custom-made steel and also aluminium items for the AV market. If you intend to use a much more exact K-factor, as opposed to use this graph, you'll require around 3-5 examination items to gather some info, including bend allowance (BA), bend distance(Ir)and also product thickness (Mt). Much more thorough details on determining the K-factor can be discovered in this short article. Below are a few of the various type of metal fabrication: In this sort of steel construction, molten metal is put into a mold or pass away, permitting it to cool down. It after that begins solidifying into the desired form, making the process sensible for mass-producing the same items. There are various kinds of spreading. The employee applies pressure to make sure it remains in location till it solidifies. One more type of casting is semi-permanent mold and mildew casting, where the molten metal is put right into molds with expendable cores, making them easier and also cheaper to eliminate. Cutting is an usual construction kind that includes cutting a metal work surface to split it into smaller sized sections. Like attracting, this procedure can be done with steel heated well over space temperature level to just under recrystallization temperature level, called warm creating.Once the temperature gets to recrystallization degrees, it is then called warm creating. It is one of the oldest kinds of steel fabrication, with the very first blacksmiths using creating to function with steel.

Report this wiki page